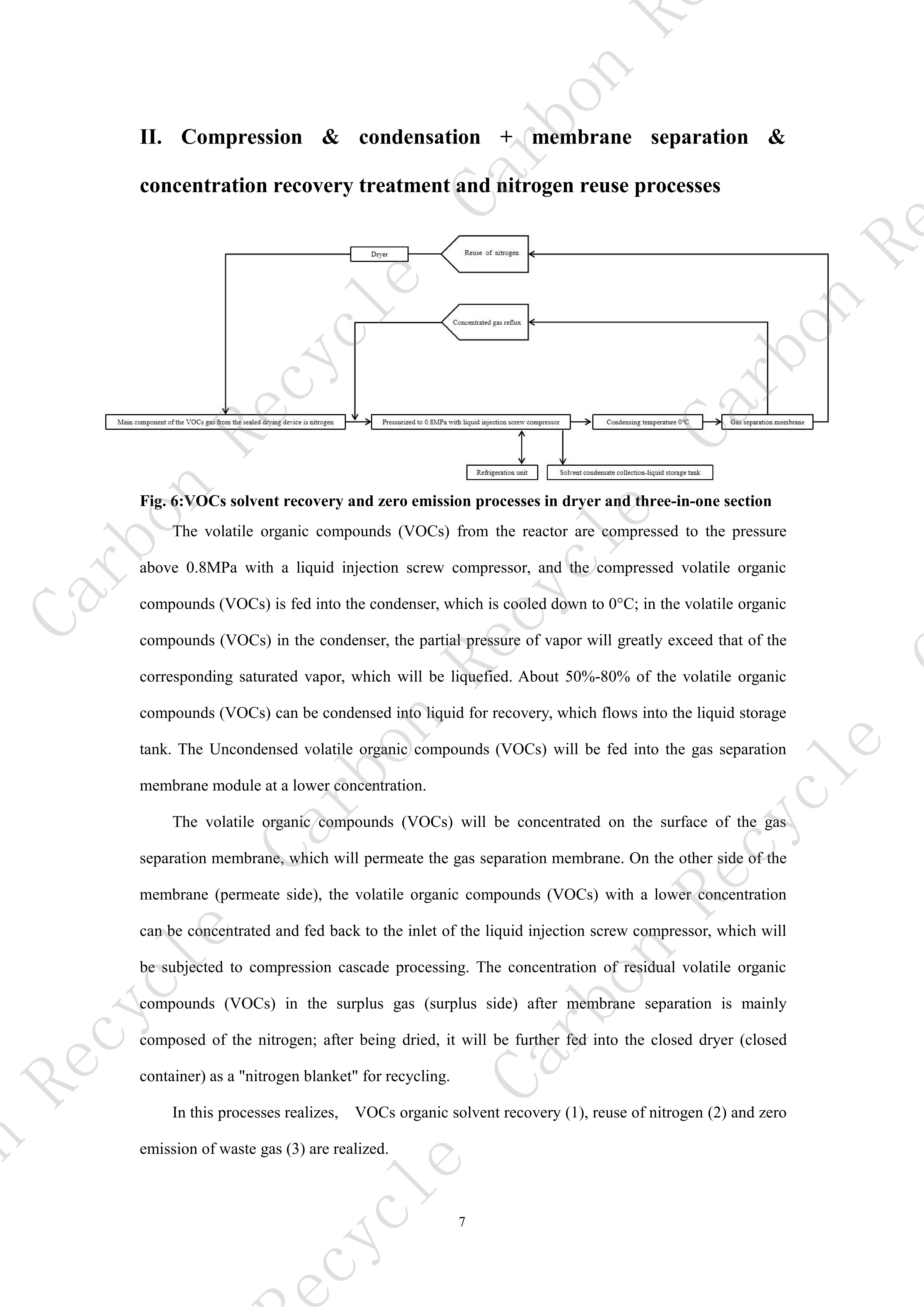

compression & condensation membrane separation & concentration recovery treatment and nitrogen reuse processes

the volatile organic compounds (vocs) from the reactor are compressed to the pressure above 0.8mpa with a liquid injection screw compressor, and the compressed volatile organic compounds (vocs) is fed into the condenser, which is cooled down to 0°c; in the volatile organic compounds (vocs) in the condenser, the partial pressure of vapor will greatly exceed that of the corresponding saturated vapor, which will be liquefied. about 50%-80% of the volatile organic compounds (vocs) can be condensed into liquid for recovery, which flows into the liquid storage tank. the uncondensed volatile organic compounds (vocs) will be fed into the gas separation membrane module at a lower concentration.